Table of Content

- What is Inconel 601 Washers

- Inconel 601 Washers Specification

- Inconel 601 Washers Equivalent Grade

- Types of Inconel 601 Washers

- Inconel 601 Washers Price List

- Size Chart Of Inconel 601 Washers

- Dimensions of Alloy 601 Spring Washer

- Weight Chart Of Inconel Alloy 601 Washers

- Chemical Composition of Grade 601 Inconel Washers

- Mechanical Properties of Inconel 601 Washers

- Other Types of Inconel 601 Washers

- Inconel 601 Washers Application Area

- Other Stock of Inconel Washers

Inconel 601 Industrial Washers, Werkstoff Nr. 2.4851 Spring Washer, Inconel 601 Washer, Best Deals on Inconel UNS N06601 Washers, ASTM B166 Alloy 601 Plain Washers, 601 Inconel Locking Washer, Inconel Alloy 601 Flat Washer, Alloy 601 Fender Washer, Inconel 601 Star Washer Supplier in India.

Kalpatru is a renowned exporter and distributor of Inconel Alloy 601 Washers, which are hardened by cold working. Inconel 601 Flat Washers offers excellent corrosion resistance in the first and the second recycling use of the high purity water in the nuclear reactor. When under the high temperature, annealing and state solution Inconel 601 Lock Washers have good antioxidant off and high-intensity in the air. Nickel-Alloy 601 Sealing Washers resists the ammonia, nitrating and carburizing atmosphere, but at the turn of the changes in redox conditions, it will be corrosion by parts of oxidation media. In polyphonic acid, Inconel 601 Split Washers showed no cracking after exposure for 720 h to a solution that cracked sensitized steel within 1 h. Inconel 601 Slot Washers is annealed at 1038°C (1900°F) followed by cooling. In deaerated 1% sodium hydroxide at 600°F (316°C), specimens of Inconel 601 Machine Washers did not crack in 9400 h. Corrosion rates for Inconel UNS N06601 Star Washers in oxidizing and reducing sulfurizing atmospheres. Petrochemical works production of catalytic regeneration in the application of more than 700°C recommended the use of Inconel 601 Spring Washers, in order to obtain a longer service life. Inconel 601 Wire Spring Washers offers especially excellent corrosion resistance to dry chlorine and chlorine hydride applied up to 650 °C. Restricted carbon plus columbium stabilization of Inconel WNR 2.4851 Flat Spring Washers permits welded fabrications to be used in corrosive environments, normally without post-weld heat treatment.

Large Selection of Inconel 601 Washers, ASME SB166 Inconel 601 Countersunk Washer, Inconel DIN 2.4851 Star Washers, High Quality Inconel 601 Ogee Washers, Inconel NCF 601 Square Washer, Inconel Alloy 601 Machine Washer, 601 Inconel Spring Washer Dealer, Alloy 601 Tooth Lock Washer, Inconel Alloy 601 Split Ring Washer, Inconel N06601 Inconel Washers Exporter.

Inconel 601 Washers Specification

Inconel 601 Washers Equivalent Grade

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 601 | N06601 | 2.4851 | NiCr23Fe | NiCr15Fe | NCF 601 | NA 49 | XH60BT | ЭИ868 |

Types of Inconel 601 Washers

Inconel 601 Dock Washer

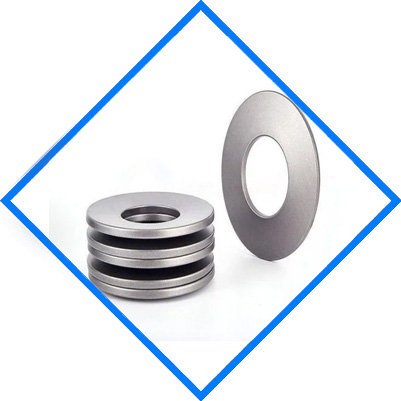

Inconel 601 Belleville Washer

Inconel 601 Fender Washer

Inconel 601 Countersunk Finishing Washer

Inconel 601 Ogee Washer

Inconel 601 Split Washer

Inconel 601 Flat Washer

Inconel 601 Star Washer

Inconel 601 Square Washers

Inconel 601 Spring Washer

Inconel 601 Lock Washer

Inconel 601 Spherical Washer

Inconel 601 Washers Price List

We offer wide range of industrial Inconel 601 Washers that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Inconel 601 Washers Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Size Chart Of Inconel 601 Washers

| Size | USS | SAE | ||||

|---|---|---|---|---|---|---|

| Inside Diameter (A) |

Outside Diameter (B) |

Thickness (C) |

Inside Diameter (A) |

Outside Diameter (B) |

Thickness (C) |

|

| #2 | – | – | – | 3/32″ | 1/4″ | 0.020″ |

| #4 | – | – | – | 1/8″ | 5/16″ | 0.032″ |

| #6 | – | – | – | 5/32″ | 3/8″ | 0.049″ |

| #8 | – | – | – | 3/16″ | 7/16″ | 0.049″ |

| #10 | – | – | – | 7/32″ | 1/2″ | 0.049″ |

| #12 | – | – | – | 1/4″ | 9/16″ | 0.065″ |

| 1/4″ | 5/16″ | 0.734″ | 0.065″ | 9/32″ | 5/8″ | 0.065″ |

| 5/16″ | 3/8″ | 7/8″ | 0.083″ | 11/32″ | 11/16″ | 0.065″ |

| 3/8″ | 7/16″ | 1″ | 0.083″ | 13/32″ | 13/16″ | 0.065″ |

| 7/16″ | 1/2″ | 1-1/4″ | 0.083″ | 15/32″ | 15/16″ | 0.065″ |

| 1/2″ | 9/16″ | 1-3/8″ | 0.109″ | 17/32″ | 1-1/16″ | 0.095″ |

| 9/16″ | 5/8″ | 1-15/32″ | 0.109″ | 19/32″ | 1-5/32″ | 0.095″ |

| 5/8″ | 11/16″ | 1-3/4″ | 0.134″ | 21/32″ | 1-5/16″ | 0.095″ |

| 3/4″ | 13/16″ | 2″ | 0.148″ | 13/16″ | 1-15/32″ | 0.134″ |

| 7/8″ | 15/16″ | 2-1/4″ | 0.165″ | 15/16″ | 1-3/4″ | 0.134″ |

| 1″ | 1-1/16″ | 2-1/2″ | 0.165″ | 1-1/16″ | 2″ | 0.134″ |

| 1-1/8″ | 1-1/4″ | 2-3/4″ | 0.165″ | – | – | – |

| 1-1/4″ | 1-3/8″ | 3″ | 0.165″ | – | – | – |

| 1-3/8″ | 1-1/2″ | 3-1/4″ | 0.180″ | – | – | – |

| 1-1/2″ | 1-5/8″ | 3-1/2″ | 0.180″ | – | – | – |

| 1-5/8″ | 1-3/4″ | 3-3/4″ | 0.180″ | – | – | – |

| 1-3/4″ | 1-7/8″ | 4″ | 0.180″ | – | – | – |

| 2″ | 2-1/8″ | 4-1/2″ | 0.213″ | – | – | – |

Dimensions of Alloy 601 Spring Washer

| NOM SIZE | Inner Dia (d) Basic Tol (+) | Outer Dia (d1) Max | WIDTH (b) Basic Tol (+ or -) | THICKNESS (S) Basic Tol (+ or -) | Weight per 1000 in Kgs | |||

| 3 | 3.1 | 0.3 | 6.2 | 1.3 | 0.1 | 0.8 | 0.1 | 0.11 |

| 4 | 4.1 | 0.3 | 7.6 | 1.5 | 0.1 | 0.9 | 0.1 | 0.18 |

| 5 | 5.1 | 0.3 | 9.2 | 1.8 | 0.1 | 1.2 | 0.1 | 0.36 |

| 6 | 6.1 | 0.4 | 11.8 | 2.5 | 0.15 | 1.6 | 0.1 | 0.83 |

| 8 | 8.1 | 0.4 | 14.8 | 3 | 0.15 | 2 | 0.1 | 1.60 |

| 10 | 10.2 | 0.5 | 18.1 | 3.5 | 0.2 | 2.2 | 0.15 | 2.53 |

| 12 | 12.2 | 0.5 | 21.1 | 4 | 0.2 | 2.5 | 0.15 | 3.82 |

| 14 | 14.2 | 0.5 | 24.1 | 4.5 | 0.2 | 3 | 0.15 | 6.01 |

| 16 | 16.2 | 0.8 | 27.4 | 5 | 0.2 | 3.5 | 0.2 | 8.91 |

| 18 | 18.2 | 0.8 | 29.4 | 5 | 0.2 | 3.5 | 0.2 | 9.73 |

| 20 | 20.2 | 1 | 33.6 | 6 | 0.2 | 4 | 0.2 | 15.20 |

| 22 | 22.5 | 1 | 35.9 | 6 | 0.2 | 4 | 0.2 | 16.50 |

| 24 | 24.5 | 1 | 40 | 7 | 0.25 | 5 | 0.2 | 26.20 |

| 27 | 27.5 | 1 | 43 | 7 | 0.25 | 5 | 0.2 | 28.70 |

| 30 | 30.5 | 1.2 | 48.2 | 8 | 0.25 | 6 | 0.2 | 44.30 |

| 33 | 33.5 | 1.2 | 55.2 | 10 | 0.25 | 6 | 0.2 | 63.00 |

| 36 | 36.5 | 1.2 | 58.2 | 10 | 0.25 | 6 | 0.2 | 67.30 |

| 39 | 39.5 | 1.2 | 61.2 | 10 | 0.25 | 6 | 0.2 | 71.70 |

| 42 | 42.5 | 1.2 | 68.2 | 12 | 0.25 | 7 | 0.25 | 111.00 |

| 45 | 45.5 | 1.2 | 71.2 | 12 | 0.25 | 7 | 0.25 | 117.00 |

| 48 | 49 | 1.5 | 75 | 12 | 0.25 | 7 | 0.25 | 123.00 |

| 52 | 53 | 1.5 | 83 | 14 | 0.25 | 8 | 0.25 | 320.00 |

Weight Chart Of Inconel Alloy 601 Washers

| APPROX. WEIGHT IN KGS FOR 100 NOS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SIZE | PLAIN PUNCHED WASHER IS:2016 |

HEAVY WASHER IS:6610 |

MACHINED WASHER IS:2016 |

SQUARE | TAPER | WASHERS | SPRING WASHER FLAT SECTION IS:3063-72 | SPRING WASHER SQUARE SECTION IS:6735-72 DIN : 7980 |

Size (Inches) | PLAIN PUNCHED WASHER BS:3410 TABLE 7 |

|||

| MACHINED | HIGH STRENGTH FRICTION GRIP |

||||||||||

| FOR CHANNELS IS:5372-75 |

FOR I-BEAM IS:5374-75 |

TYPE-B (CHANNELS) IS : 6649-85 |

TYPE-C ( I-BEAMS ) IS : 6649-85 |

||||||||

| M-3 | 0.01 | 0.01 | |||||||||

| M-4 | 0.02 | 0.02 | |||||||||

| M-5 | 0.04 | 0.04 | 0.03 | 0.03 | |||||||

| M-6 | 0.11 | 0.11 | 0.08 | 0.04 | 1/4″ | 0.21 | |||||

| M-8 | 0.20 | 0.21 | 1.10 | 1.20 | 0.16 | 0.11 | 5/16″ | 0.35 | |||

| M-10 | 0.39 | 1.60 | 0.40 | 1.00 | 1.10 | 0.25 | 0.20 | 3/8″ | 0.48 | ||

| M-12 | 0.58 | 1.90 | 0.62 | 2.00 | 2.20 | 2.00 | 1.80 | 0.38 | 0.23 | 1/2″ | 1.07 |

| M-14 | 0.82 | 0.60 | 0.38 | ||||||||

| M-16 | 1.06 | 2.90 | 1.13 | 3.40 | 3.75 | 9.00 | 8.50 | 0.89 | 0.59 | 5/8″ | 1.85 |

| M-18 | 1.27 | 0.97 | 0.66 | ||||||||

| M-20 | 1.64 | 4.40 | 1.72 | 5.80 | 6.70 | 8.50 | 8.00 | 1.52 | 1.23 | 3/4″ | 2.91 |

| M-22 | 1.75 | 7.50 | 7.00 | 1.65 | 1.36 | 7/8″ | 4.27 | ||||

| M-24 | 3.11 | 6.30 | 3.30 | 13.50 | 16.00 | 6.50 | 6.00 | 2.62 | 1.81 | 1″ | 6.13 |

| M-27 | 3.94 | 8.00 | 4.23 | 12.50 | 15.00 | 12.00 | 11.50 | 2.87 | 2.06 | 1.1/8″ | 7.69 |

| M-30 | 5.05 | 10.10 | 5.36 | 16.50 | 18.70 | 17.50 | 16.00 | 4.43 | 3.20 | 1.1/4″ | 9.90 |

| M-33 | 7.10 | 12.00 | 7.54 | 21.00 | 23.50 | 23.00 | 22.50 | 6.30 | 3.50 | ||

| M-36 | 8.73 | 14.60 | 9.20 | 25.50 | 29.20 | 26.50 | 26.00 | 6.73 | 5.25 | 1.1/2″ | 17.24 |

| M-39 | 12.60 | 16.70 | 13.30 | 28.30 | 34.50 | 7.17 | 5.61 | ||||

| M-42 | 17.50 | 20.10 | 18.30 | 11.10 | 8.00 | ||||||

| M-45 | 21.20 | 22.20 | 22.00 | 11.70 | 8.53 | ||||||

| M-48 | 28.40 | 26.00 | 29.40 | 12.30 | 9.00 | 2″ | 27.78 | ||||

| M-52 | 31.90 | 33.00 | 18.20 | ||||||||

| M-56 | 47.90 | 19.30 | |||||||||

| M-60 | 51.60 | 20.30 | |||||||||

| M-64 | 55.40 | 21.80 | |||||||||

| M-68 | 57.40 | ||||||||||

| M-72 | 63.40 | 24.00 | |||||||||

Chemical Composition of Grade 601 Inconel Washers

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Mechanical Properties of Inconel 601 Washers

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Other Types of Inconel 601 Washers

Inconel 601 Washer

Inconel 601 Dome Washer

Inconel Alloy 601 Hex Washers

ASTM B166 Inconel 601 Tab Washer

601 Inconel Conical Washers

Inconel Alloy 601 Lock Washer

Inconel 2.4851 Cup Washers

Inconel 601 Washers Stockist

UNS N06601 Belleville Washers Supplier

ASME SB166 Inconel 601 Wave Washer

601 Inconel Alloy Bevel Washers

601 Inconel Sealing Washer

ASME SB166 Inconel 601 Hexagon Washer

Inconel NCF 601 Machine Washer

Alloy 601 Dock Washers Exporter

Inconel N06601 Inconel Split Lock Washer

Inconel 601 Hillside Washers Stockholder

Inconel 601 Bearing Lock Washers

Inconel 601 Spherical Washers in Mumbai

INOX 2.4851 Split /Lock Washer

Inconel 601 NiCr15Fe Lock Washer

Inconel 601 BS NA 14 Tab Washers

INOX 2.4851 Square Washers

ASME SB166 Inconel 601 Machined Washers

Inconel N06601 Spherical Washer

Inconel Alloy 601 Tooth Lock Washer

Inconel Alloy 601 Machined Washers

Alloy 601 Washer Specification

Alloy 601 Tooth Washer

601 Inconel Alloy C Washer

601 Inconel Finishing Washers

Inconel 601 Hillside Washers

Grade 601 Inconel Spherical Washers Manufacturer

Inconel 601 Washers Distributor

Inconel Alloy 601 Taper Washers

Inconel 601 Industrial Washer Price

ASTM B166 Alloy 601 Serrated Washer

Inconel UNS N06601 Split Washer

Inconel DIN 2.4851 Spring Washer

601 Inconel Alloy Split Ring Washers

601 Inconel Star Lock Washer

Inconel Alloy 601 Tooth Lock Washer

Alloy 601 Hexagonal Washer Dealer

Inconel 601 Slotted Washers

Inconel GOST XH60BT Customized Washer

Inconel 601 Dome Tooth Washers

ASTM B166 Industrial Washers Supplier in India

Inconel JIS NCF 601 Flat Washers

Inconel 601 Countersunk Washers

Inconel 601 Wedge Lock Washers

Inconel 601 AFNOR NC23FeA Punched Washer

Inconel 601 ASTM B166 Fender Washers

Inconel 601 AFNOR NC23FeA Punched Washer

Inconel 601 Wedge Lock Washers

Inconel 601 Dome Tooth Washers

Inconel Alloy N06601 Washers

Inconel 601 Washers Application Area

Our products range of Inconel 601 Washers find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.