Best Deals on Raised Face Lap Joint Flanges, Carbon Steel Lap Joint Flange, Nickel Alloy Lap Joint Flanges, ASME / ANSI B16.5 Lap Joint Flanges, ANSI B16.5 Lap Joint Flanges, Class 300 Lap Joint Flanges, ASME B16.5 Raised Face Lap Joint Flange, Stainless Steel Lapped Joint Flange Supplier in India.

Kalpataru Piping Solutions is a popular seller of Lap Joint Flanges, which are used for corrosion-resistant tools. Stainless Steel Lap Joint Flanges is resistant to stress corrosion cracking and crevice corrosion. Carbon Steel Lap Joint Flanges is non-magnetic, and offers excellent formability, toughness and weldability. Alloy Steel Lap Joint Flanges contains high amounts of expensive ingredients, such as molybdenum and nickel. The addition of copper to this Super Duplex Steel Lap Joint Flanges gives it corrosion resistant properties superior to the conventional chrome nickel steels, in particular to sulphuric, phosphoric and acetic acids. Nickel Alloy Lap Joint Flanges is non-magnetic in all conditions and has excellent formability and weldability. Monel Lap Joint Flanges was originally developed to withstand environments containing dilute sulphuric acid. Inconel Lap Joint Flanges also offers good resistance to other inorganic acids such as hot phosphoric acid as well as most organic acids. Hastelloy Lap Joint Flanges is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications. Titanium Lap Joint Flanges does not readily corrode, rust or stain with water as ordinary steel does. However, Copper Nickel Lap Joint Flanges is not fully stain-proof in low-oxygen, high-salinity, or poor air-circulation environments. There are various grades and surface finishes of Alloy 20 Lap Joint Flanges to suit the environment the alloy must endure. SMO 254 Lap Joint Flanges differs from carbon steel by the amount of chromium present.

Large Selection of Inconel Lap Joint Flanges, Hastelloy Lap Joint Flange Dealer, Alloy Steel Lapped Joint Flanges, ANSI B16.5 Lapped Joint Flange, ANSI B16.5 150 LBS Lap Joint Flange, High Quality Duplex Steel Lapped Joint Flanges, Class 1500 Lap Joint Flanges, Monel Lap Joint Flanges, SS Lap Joint Flanges, ANSI/ASME B16.5 Class 600 Lapped Joint Flange Exporter.

ASME B16.5 Lap Joint Flanges Specification

Lap Joint Flanges Material & Grades

| Stainless Steel Lap Joint Flanges | |

| ASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L | |

| Carbon Steel Lap Joint Flanges | |

| ASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70 | |

| Alloy Steel Lap Joint Flanges | |

| ASTM A182, F1, F5, F9, F11, F22, F91 | |

| Duplex Steel Lap Joint Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| Super Duplex Lap Joint Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| High Nickel Alloy Lap Joint Flanges | |

| ASTM B564, B160, B472, B162, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade 2 & 5), Cupro-Nickel 70/30, Cupro-Nickel 90/10. | |

| Low Temperature Carbon Steel Lap Joint Flanges | |

| ASTM A350, LF2, LF3 | |

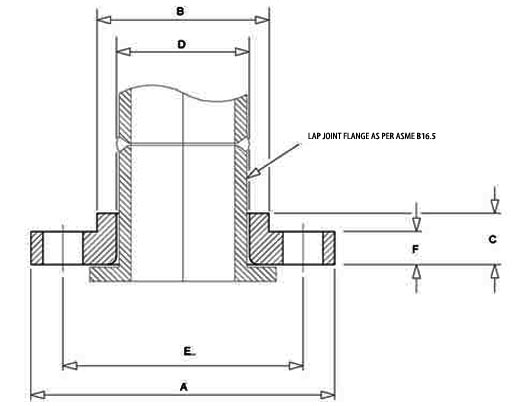

Dimensions of Lap Joint Flanges

150 lb Class Flange Dimensions

| Size in Inch | Size in mm | Outer Diameter | Flange Thick. | Lapped Thick. | Lapped ID | PCD | Lapped Thick. | Lapped Radius | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | G | ||||||||||

| 1/2 | 15 | 90 | 30 | 16 | 22.9 | 60.3 | 11.2 | 3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 38 | 16 | 28.2 | 69.9 | 12.7 | 3 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 49 | 17 | 34.9 | 79.4 | 14.3 | 3 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 59 | 21 | 43.7 | 88.9 | 15.9 | 5 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 65 | 22 | 50 | 98.4 | 17.5 | 6 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 78 | 25 | 62.5 | 120.7 | 19.1 | 8 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 90 | 29 | 75.4 | 139.7 | 22.3 | 8 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 108 | 30 | 91.4 | 152.4 | 23.9 | 10 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 122 | 32 | 104.1 | 177.8 | 23.9 | 11 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 135 | 33 | 116.8 | 190.5 | 23.9 | 11 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 164 | 36 | 144.4 | 215.9 | 23.9 | 11 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 192 | 40 | 171.4 | 241.3 | 25.4 | 13 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 246 | 44 | 222.2 | 298.5 | 28.6 | 13 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 305 | 49 | 277.4 | 362 | 30.2 | 13 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 365 | 56 | 328.2 | 431.8 | 31.8 | 13 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 400 | 79 | 360.2 | 476.3 | 35 | 13 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 457 | 87 | 411.2 | 539.8 | 36.6 | 13 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 505 | 97 | 462.3 | 577.9 | 39.7 | 13 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 559 | 103 | 514.4 | 635 | 42.9 | 13 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 663 | 111 | 616 | 749.3 | 47.9 | 13 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Lap Joint Flange Class 300 Dimensions

Nominal Bore |

Dia. (D) |

Thick. (E) |

Dia. (B) |

Dia. (A) |

Height (H) |

Nbr |

Holes |

Dia. (C) |

|---|---|---|---|---|---|---|---|---|

1/2" |

95 |

14.3 |

38 |

22.9 |

22 |

4 |

15.87 |

66.7 |

3/4" |

115 |

15.9 |

48 |

28.2 |

25 |

4 |

19.05 |

82.6 |

1" |

125 |

17.5 |

54 |

34.9 |

27 |

4 |

19.05 |

88.9 |

1 1/4" |

135 |

19.1 |

64 |

43.7 |

27 |

4 |

19.05 |

98.4 |

1 1/2" |

155 |

20.7 |

70 |

50.0 |

30 |

4 |

22.22 |

114.3 |

2" |

165 |

22.3 |

84 |

62.5 |

33 |

8 |

19.05 |

127.0 |

2 1/2" |

190 |

25.4 |

100 |

75.4 |

38 |

8 |

22.22 |

149.2 |

3" |

210 |

28.6 |

117 |

91.4 |

43 |

8 |

22.22 |

168.3 |

3 1/2" |

230 |

30.2 |

133 |

104.1 |

44 |

8 |

22.22 |

184.2 |

4" |

255 |

31.8 |

146 |

116.8 |

48 |

8 |

22.22 |

200.0 |

5" |

280 |

35.0 |

178 |

144.4 |

51 |

8 |

22.22 |

235.0 |

6" |

320 |

36.6 |

206 |

171.4 |

52 |

12 |

22.22 |

269.9 |

8" |

380 |

41.3 |

260 |

222.2 |

62 |

12 |

25.40 |

330.2 |

10" |

445 |

47.7 |

321 |

277.4 |

95 |

16 |

28.57 |

387.4 |

12" |

520 |

50.8 |

375 |

328.2 |

102 |

16 |

31.75 |

450.8 |

14" |

585 |

54.0 |

425 |

360.2 |

111 |

20 |

31.75 |

514.4 |

16" |

650 |

57.2 |

483 |

411.2 |

121 |

20 |

34.29 |

571.5 |

18" |

710 |

60.4 |

533 |

462.3 |

130 |

24 |

34.29 |

628.6 |

20" |

775 |

63.5 |

587 |

514.4 |

140 |

24 |

34.29 |

685.8 |

24" |

915 |

69.9 |

702 |

616.0 |

152 |

24 |

41.27 |

812.8 |

Class 600 Lap Joint Flange Dimensions

Nominal Bore |

Dia. (D) |

Thick. (E) |

Dia. (B) |

Dia. (A) |

Height (H) |

Nbr |

Holes |

Dia. (C) |

|---|---|---|---|---|---|---|---|---|

1/2" |

95 |

14.3 |

38 |

23.6 |

22 |

4 |

15.87 |

66.7 |

3/4" |

115 |

15.9 |

48 |

29.0 |

25 |

4 |

19.05 |

82.6 |

1" |

125 |

17.5 |

54 |

35.8 |

27 |

4 |

19.05 |

88.9 |

1 1/4" |

135 |

20.7 |

64 |

44.4 |

29 |

4 |

19.05 |

98.4 |

1 1/2" |

155 |

22.3 |

70 |

50.6 |

32 |

4 |

22.22 |

114.3 |

2" |

165 |

25.4 |

84 |

63.5 |

37 |

8 |

19.05 |

127.0 |

2 1/2" |

190 |

28.6 |

100 |

76.2 |

41 |

8 |

22.22 |

149.2 |

3" |

210 |

31.8 |

117 |

92.2 |

46 |

8 |

22.22 |

168.3 |

3 1/2" |

230 |

35.0 |

133 |

104.9 |

49 |

8 |

25.40 |

184.2 |

4" |

275 |

38.1 |

152 |

117.6 |

54 |

8 |

25.40 |

215.9 |

5" |

330 |

44.5 |

189 |

144.4 |

60 |

8 |

28.57 |

266.7 |

6" |

355 |

47.7 |

222 |

171.4 |

67 |

12 |

28.57 |

292.1 |

8" |

420 |

55.6 |

273 |

222.2 |

76 |

12 |

31.75 |

349.2 |

10" |

510 |

63.5 |

343 |

276.2 |

111 |

16 |

34.92 |

431.8 |

12" |

560 |

66.7 |

400 |

328.6 |

117 |

20 |

34.92 |

489.0 |

14" |

605 |

69.9 |

432 |

360.4 |

127 |

20 |

38.10 |

527.0 |

16" |

685 |

76.2 |

495 |

411.2 |

140 |

20 |

41.27 |

603.2 |

18" |

745 |

82.6 |

546 |

462.0 |

152 |

20 |

44.45 |

6654.0 |

20" |

815 |

88.9 |

610 |

512.8 |

165 |

24 |

44.45 |

723.9 |

24" |

940 |

101.6 |

718 |

614.4 |

184 |

24 |

50.80 |

838.2 |

Dimensions Table of Lap Joint Flange Class 900

Size in Inch |

Size in mm |

Outer Diameter |

Flange Thick. |

Lapped Thick. |

Lapped ID |

PCD |

Lapped Thick. |

Lapped Radius |

No of Bolts |

Bolt Size UNC |

RF Stud Length |

Hole Size |

ISO Stud Size |

Weight in kg |

A |

B |

C |

D |

E |

G |

|||||||||

1/2 |

15 |

120 |

38 |

32 |

22.9 |

82.6 |

22.3 |

3 |

4 |

3/4 |

110 |

7/8 |

M20 |

1.8 |

3/4 |

20 |

130 |

44 |

35 |

28.2 |

88.9 |

25.4 |

3 |

4 |

3/4 |

115 |

7/8 |

M20 |

2.3 |

1 |

25 |

150 |

52 |

41 |

34.9 |

101.6 |

28.6 |

3 |

4 |

7/8 |

125 |

1 |

M24 |

3.6 |

1 1/4 |

32 |

160 |

64 |

41 |

43.7 |

111.1 |

28.6 |

5 |

4 |

7/8 |

125 |

1 |

M24 |

4.1 |

1 1/2 |

40 |

180 |

70 |

44 |

50 |

123.8 |

31.8 |

6 |

4 |

1 |

140 |

1 1/8 |

M27 |

5.5 |

2 |

50 |

215 |

105 |

57 |

62.5 |

165.1 |

38.1 |

8 |

8 |

7/8 |

145 |

1 |

M24 |

11.5 |

2 1/2 |

65 |

245 |

124 |

64 |

75.4 |

190.5 |

41.3 |

8 |

8 |

1 |

160 |

1 1/8 |

M27 |

16.5 |

3 |

80 |

240 |

127 |

54 |

91.4 |

190.5 |

38.1 |

10 |

8 |

7/8 |

145 |

1 |

M24 |

12 |

4 |

100 |

290 |

159 |

70 |

116.8 |

235 |

44.5 |

11 |

8 |

1 1/8 |

170 |

1 1/4 |

M30 |

24 |

5 |

125 |

350 |

190 |

79 |

144.4 |

279.4 |

50.8 |

11 |

8 |

1 1/4 |

190 |

1 3/8 |

M33 |

38 |

6 |

150 |

380 |

235 |

86 |

171.4 |

317.5 |

55.6 |

13 |

12 |

1 1/8 |

190 |

1 1/4 |

M30 |

50 |

8 |

200 |

470 |

298 |

114 |

222.2 |

393.7 |

63.5 |

13 |

12 |

1 3/8 |

220 |

1 1/2 |

M36 |

78 |

10 |

250 |

545 |

368 |

127 |

277.4 |

469.9 |

69.9 |

13 |

16 |

1 3/8 |

235 |

1 1/2 |

M36 |

112 |

12 |

300 |

610 |

419 |

143 |

328.2 |

533.4 |

79.4 |

13 |

20 |

1 3/8 |

255 |

1 1/2 |

M36 |

148 |

14 |

350 |

640 |

451 |

156 |

360.2 |

558.8 |

85.8 |

13 |

20 |

1 1/2 |

275 |

1 5/8 |

M39 |

182 |

16 |

400 |

705 |

508 |

165 |

411.2 |

616 |

88.9 |

13 |

20 |

1 5/8 |

285 |

1 3/4 |

M42 |

193 |

18 |

450 |

785 |

565 |

190 |

462.3 |

685.8 |

101.6 |

13 |

20 |

1 7/8 |

325 |

2 |

M48 |

258 |

20 |

500 |

855 |

622 |

210 |

514.4 |

749.3 |

108 |

13 |

20 |

2 |

350 |

2 1/8 |

M52 |

317 |

24 |

600 |

1040 |

749 |

267 |

616 |

901.7 |

139.7 |

13 |

20 |

2 1/2 |

440 |

2 5/8 |

M64 |

608 |

Dimensions of Class 1500 Lap Joint Flange

Size in Inch |

Size in mm |

Outer Diameter |

Flange Thick. |

Lapped Thick. |

Lapped ID |

PCD |

Lapped Thick. |

Lapped Radius |

No of Bolts |

Bolt Size UNC |

RF Stud Length |

Hole Size |

ISO Stud Size |

Weight in kg |

A |

B |

C |

D |

E |

G |

|||||||||

1/2 |

15 |

120 |

38 |

32 |

22.9 |

82.6 |

22.3 |

3 |

4 |

3/4 |

110 |

7/8 |

M20 |

1.8 |

3/4 |

20 |

130 |

44 |

35 |

28.2 |

88.9 |

25.4 |

3 |

4 |

3/4 |

115 |

7/8 |

M20 |

2.3 |

1 |

25 |

150 |

52 |

41 |

34.9 |

101.6 |

28.6 |

3 |

4 |

7/8 |

125 |

1 |

M24 |

3.7 |

1 1/4 |

32 |

160 |

64 |

41 |

43.7 |

111.1 |

28.6 |

5 |

4 |

7/8 |

125 |

1 |

M24 |

4.1 |

1 1/2 |

40 |

180 |

70 |

44 |

50 |

123.8 |

31.8 |

6 |

4 |

1 |

140 |

1 1/8 |

M27 |

5.5 |

2 |

50 |

215 |

105 |

57 |

62.5 |

165.1 |

38.1 |

8 |

8 |

7/8 |

145 |

1 |

M24 |

9.8 |

2 1/2 |

65 |

245 |

124 |

64 |

75.4 |

190.5 |

41.3 |

8 |

8 |

1 |

160 |

1 1/8 |

M27 |

16.4 |

3 |

80 |

265 |

133 |

73 |

91.4 |

203.2 |

47.7 |

10 |

8 |

1 1/8 |

180 |

1 1/4 |

M30 |

21.8 |

4 |

100 |

310 |

162 |

90 |

116.8 |

241.3 |

54 |

11 |

8 |

1 1/4 |

195 |

1 3/8 |

M33 |

33 |

5 |

125 |

375 |

197 |

105 |

144.4 |

292.1 |

73.1 |

11 |

8 |

1 1/2 |

250 |

1 5/8 |

M39 |

59 |

6 |

150 |

395 |

229 |

119 |

171.4 |

317.5 |

82.6 |

13 |

12 |

1 3/8 |

260 |

1 1/2 |

M36 |

75 |

8 |

200 |

485 |

292 |

143 |

222.2 |

393.7 |

92.1 |

13 |

12 |

1 5/8 |

290 |

1 3/4 |

M42 |

118 |

10 |

250 |

585 |

368 |

178 |

277.4 |

482.6 |

108 |

13 |

12 |

1 7/8 |

335 |

2 |

M48 |

198 |

12 |

300 |

675 |

451 |

219 |

328.2 |

571.5 |

123.9 |

13 |

16 |

2 |

375 |

2 1/8 |

M52 |

264 |

14 |

350 |

750 |

495 |

241 |

360.2 |

635 |

133.4 |

13 |

16 |

2 1/4 |

405 |

2 3/8 |

M56 |

341 |

16 |

400 |

825 |

552 |

260 |

411.2 |

704.8 |

146.1 |

13 |

16 |

2 1/2 |

445 |

2 5/8 |

M64 |

454 |

18 |

450 |

915 |

597 |

276 |

462.3 |

774.7 |

162 |

13 |

16 |

2 3/4 |

495 |

2 7/8 |

M72 |

590 |

20 |

500 |

985 |

641 |

292 |

514.4 |

831.8 |

177.8 |

13 |

16 |

3 |

540 |

3 1/8 |

M76 |

792 |

24 |

600 |

1170 |

762 |

330 |

616 |

990.6 |

203.2 |

13 |

16 |

3 1/2 |

615 |

3 5/8 |

M90 |

1248 |

ASME B16.5 Lap Joint Flanges Price List

We offer wide range of industrial Lap Joint Flanges that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Stainless Steel Lap Joint Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Other Types of Lap Joint Flanges

Stainless Steel Lap Joint Flanges

ASTM A403 SS Lap Joint Flanges

Raised Face Lap Joint Flanges

ASME B16.5 Lap Joint Flanges Specification

ASME B16.5 Class 150 Lap Joint Flanges

Duplex Steel 2205 Lap Joint Flanges Exporter

ASME B16.5 Lapped Joint Flanges Stockist

ANSI/ ASME B 16.5 Lap Joint Flanges Stockist

ANSI B16.5 Lap Joint Flanges Supplier

ASME/ANSI B16.5 Lapped Joint Flange

Carbon Steel Lapped Joint Flanges

Super Duplex 2507 Lap Joint Flanges

ANSI B16.5 Lap Joint Flanges Distributor

Monel Lap Joint Flange

ASME B16.5 Lap Joint Flanges Price

ANSI B16.5 Lap Joint Raised Face Flanges

PN16/3 Lapped Joint Flange Price

Alloy Steel Lap Joint Flanges

Lapped Joint Flange Manufacturer

Nickel Alloy Lapped Joint Flanges

ASME B16.5 Inconel Lap Joint Flanges

ANSI/ASME B16.5 Hastelloy Lapped Joint Flanges

Copper Nickel Lap Joint Flanges Dealer

Titanium Alloy Lapped Joint Flanges

Lap Joint Flanges Application Area

Our products range of Lap Joint Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.